Home

Company

Systems

Applications

Work in progress

Contacts

Experience Magnetense's

new generation of magnetic separation systems

We build powerful MAGNETIC SEPARATORS: (up to 21.000 Gauss) and also the raw material (ferrite, neodymium).

22 years of experience: we combine power with innovative mechanical engineering, resulting from reserch and development.

COSTRUZIONI NAZZARENO (Italy)

Project Manager

Mr. Giuseppe Zuccon

1. Our drum jacket was wearing too quickly and we also wanted a magnetic separated that would remove small ferrous parts during the production process..

2. What product did you purchase?

Ferrite magnetic drum.

3. What result did you get?

We achieved the …. removal distance related the test is 170mm which is good. We also noticed the quality of drum is excellent..

4. Would you recommend us?

Yes, we would recommend you.

AUTEFA SOLUTIONS

Manager Head of Technical Department

Mr. Valter Garbi

1. We had no specific problems; we just needed to reduce our maintenance and supply costs.

2. What product did you purchase?

Magnetic rod for our chargers.

3. What result did you get?

We conducted a comparative test on our previous and new magnetic separators and found the Magnatense product has far greater magnetic separation efficiency.

4. Would you recommend us?

Yes, we would recommend you.

CEPI SPA (Italy)

Purchase Manager

Ing. Luca Ceccarelli

1. What product did you purchase?

Neodymium rods.

2. What result did you get?

We found the magnetic performance in our machine significantly improved once we installed your rods. We were able to develop 13,500 Gauss in contact with the pipe and 14,250 on the outside.

3. Would you recommend us?

Yes, we would recommend you because your solution offers outstanding magnetic performance compared to other available systems.

GRESPAN IMPIANTI TECNOLOGICI SRL (Italy)

Technical Manager

Mr. Luca Durante

1. What product did you purchase?

We purchased magnetic plates with the neodymium magnet which we installed on a batch feeder for our hammer mill.

2. What was the problem?

We needed to remove metal parts that could go into the mill.

3. What result did you get?

We successfully removed all unwanted metallic parts.

4. Would you recommend us?

Yes, we would recommend you as suppliers of magnetic systems.

MOLITECNICA SUD SNC (Italy)

Engineering Departure

Mr. Vito Lomorno

1. What was the problem?

We were using a system where we couldn't separate the iron from unwanted parts.

2. What product did you purchase?

Magnetic pulleys and neodymium rings.

3. What result did you get?

We achieved a substantial increment in magnetic separation and an improved customer satisfaction rate from our own customers.

4. Would you recommend us?

Yes, we would recommend you for your technical expertise and customer service.

FALCONI ENGINEERING CM SRL (Italy)

Technical Manager

Mr. Giovanni Bianchi

1. What was the problem?

We could not prevent ferrous parts from accidentally entering the hammer mill.

2. What product did you purchase?

Ferritic magnetic plate.

3. What result did you get?

The magnetic plate we purchased has prevented all ferrous objects from entering the upper part of the mill.

4. Would you recommend us?

Yes, without any doubt we would recommend you and your product.

GIORDANO COSTRUZIONI MECCANICHE (Italy)

Chief Executive

Sig. Giordano Luca

1. What was the problem?

Intercepting iron particles flowing in a pipe used to pneumatically load flour from cisterns to silos.

2. What product did you purchase?

Pressurised magnetic piping.

3. What result did you get?

The pneumatically loaded flour is free from ferrous particles and it is now safe to move to the next process steps. The machinery is protected from ferrous contaminants.

4. Would you recommend us?

Yes, we would definitely recommend you.

BECCARIA SRL (Italy)

Purchase Manager

Sig. Paolo Massano

1. What was the problem?

Our existing magnetic system did not remove iron from the mill feeders at a satisfactory rate.

2. What product did you purchase?

We purchased the Neodymium or ferrite sticks with a 32mm diameter and a 200mm length.

3. What result did you get?

We achieved a significant improvement in the removal rate when compared with the previous system.

4. Would you recommend us?

Yes, I would recommend you.

CIMES SRL (Italy)

Purchase Manager

Sig.ra Stefania Manelli

1. What was the problem?

Compartment in enamel filters.

2. What product did you purchase?

We purchased a magnetic bar with a 32 diameter and 70 mm length.

3. What result did you get?

We obtained good results..

4. Would you recommend us?

Yes, I would recommend you.

Magnetense is a world class producer of affordable and high quality magnetic systems.

Established in Italy in 2000 to meet the growing demand for reliable and robust magnetic systems, Magnetense today is a world leader in the efficient design, build and distribution of state-of-the-art magnets, magnetic systems and consultancy services. Products provided by Magnetence include ferrite/neodymium magnets; manufacturing; and production of magnetic separators such as drums, rolls, plates, overbands, pipings, filters, rods, bars and textile rods.

Products provided by Magnetence include ferrite/neodymium magnets; manufacturing; and production of magnetic separators such as drums, rolls, plates, overbands, pipings, filters, rods, bars and textile rods.

OUR MAGNETIC SEPARATION SYSTEMS

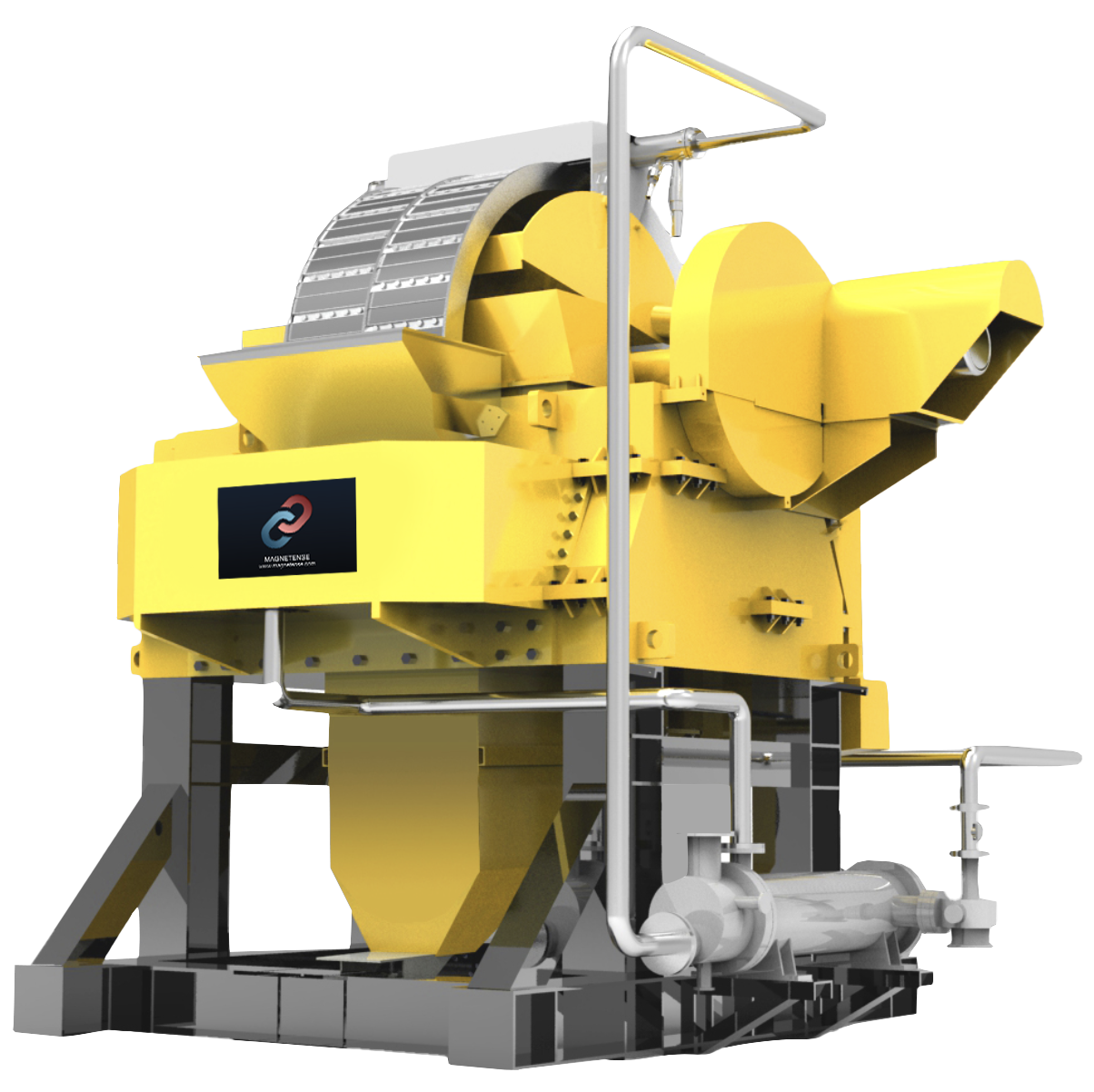

WHIMS

Wet High Intensity Magnetic Separator

The WHIMS separator is a magnetic separation machine used in wet separation processes to treat fine grain materials which are smaller than 1.2mm or 200 mesh. These fine grain materials include red mine hematite, limonite, manganese ore, and ilmenite. The WHIMS is also used to treat magnetic minerals including quartz, feldspar, nepheline ore, and kaolin. This system removes iron contaminants to concentrate the treated minerals.

Balance 2

Magnetic Drum

The Balance 2 Drum Magnet features a maximum 10,000 Gauss magnetic power: among the most powerful available on the market.

This drum achieves an excellent wear resistance which is due to Magnetense’s unique “BL2” balancing system. The BL2 is designed to be easily assembled and tested.

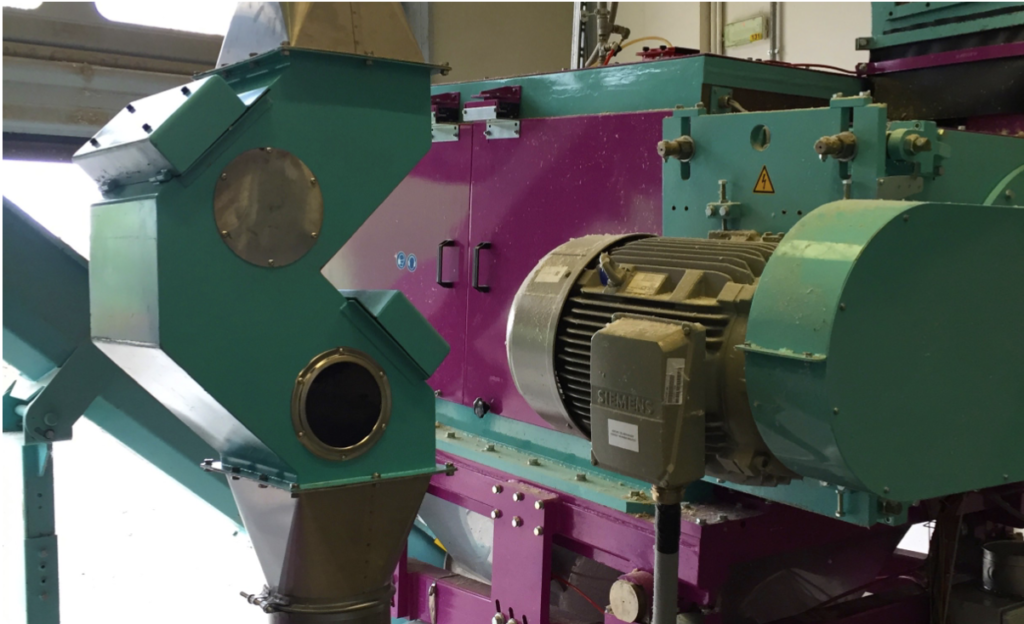

DM1-DP

MAGNETIC SORTER

Our machine DM1 is constructed for one magnetic separation passage.

It is used to separate powders and granular raw materials.

“RO” & “FLY”

MAGNETIC RODS

The “RO” and “FLY” magnetic rods are newly “reinvented” rods that have been specifically designed and built by the team at Magnetense. The RO models have a magnetic power of between 6,500 and 12,000 Gauss and the FLY model achieves a maximum power of 14,000 Gauss. The RO and FLY rods are made from high grade neodymium with single section mechanical structures and no moving parts. All rods have exceptional wear resistance.

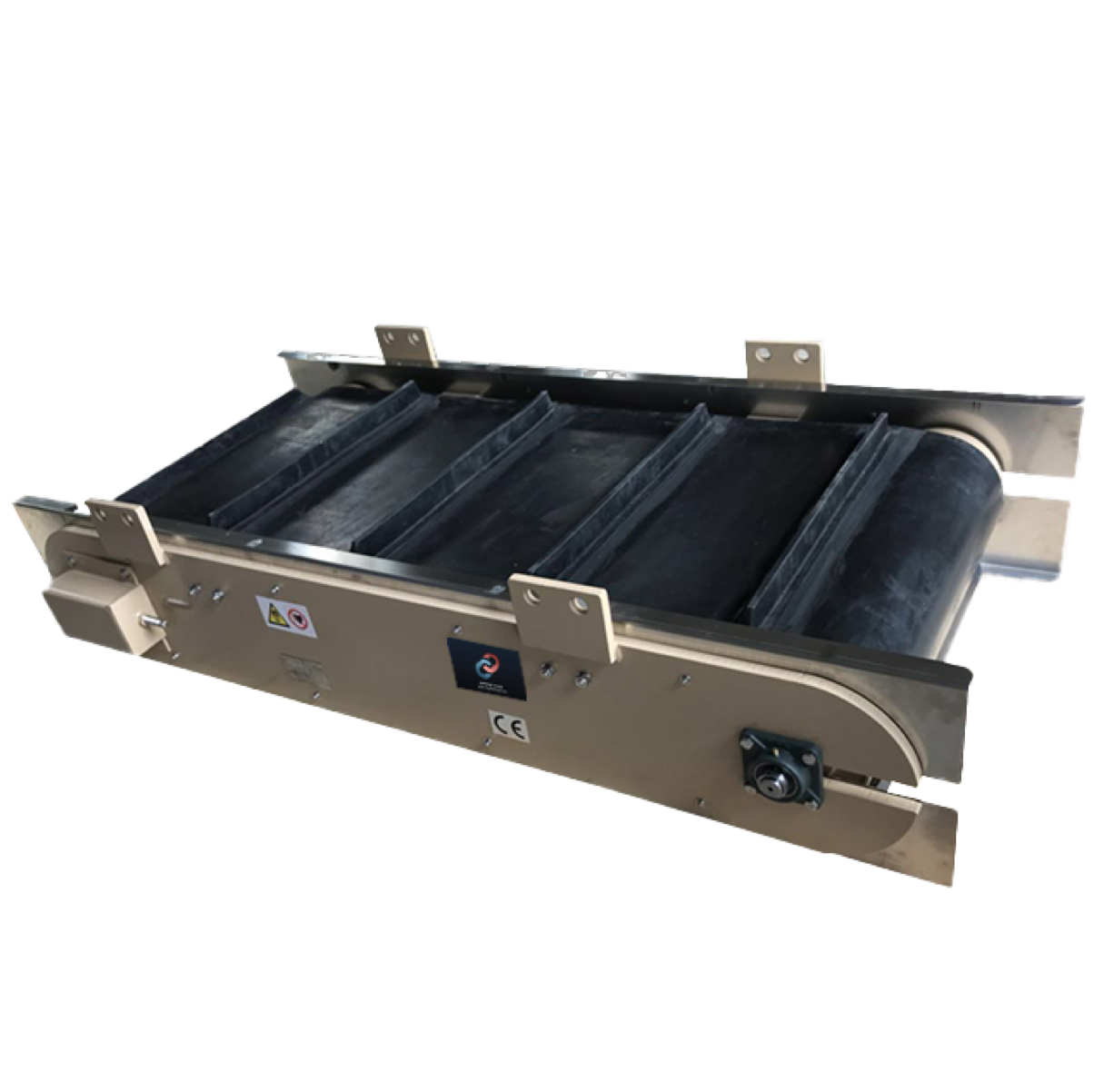

“SHARK” AND “O.VA”

OVERBAND-OVERBELT

The Overband Shark and Ova magnetic belts have been uniquely designed to include a combination of ferrite and neodymium magnets. Older generation conveyor belts were generally only fitted with ferrite magnets. This new belt design enables producers to reach more than 5507 Gauss along with a 10 per cent lighter structure when compared to other industry-standard overbelts.

GRAVITY FEED (“PI.va”), PNEUMATIC (“PI.vc”)

AND ELECTRIC (“PI.ve”)

PIPE MAGNETS

The Gravity Feed, Pneumatic Pipe and Electric Pipe magnets comprise a specialist mechanical structure that guarantees higher than industry standard wear resistance. The structure is made from high grade neodymium which allows users to achieve 20% per cent more power than our older generation pipe magnets.