In a magnetic system, power is the main thing

Magnetense is an engineering and manufacturing company.

Magnetense produce both ferrite and neodymium magnets used in magnetic separation systems serving the following industries:

-

Mining

-

Milling and grain

-

Wood

-

Textile

Magnetense manufacture powerful and efficient magnets and we use them in our magnetic systems.

We manufacture magnetic systems achieving higher efficiency compared to traditional ones in terms of magnetic field intensity (Gauss); in terms of material efficiency and, above all, in terms of iron absorption capacity.

Our clients will achieve higher results in less time.

Our History

Magnetense history started with Piero Martinazzo Perolon, father of the current CEO, Matteo.

Piero worked in the design of textile machinery focussing on fibre re-generation and magnetic systems to separate iron.

From this experience an extended network of relationship was established both with suppliers and end users around the world.

The experience and knowledge was then transferred to the son, Matteo; with the new management in place the Company entered in a new phase embracing the challenge to become a leader in the design and manufacturing of innovative magnetic separation systems.

The greatest achievement in design has been reached with the “BAL 2” balanced magnetic drum which is a unique design worldwide.

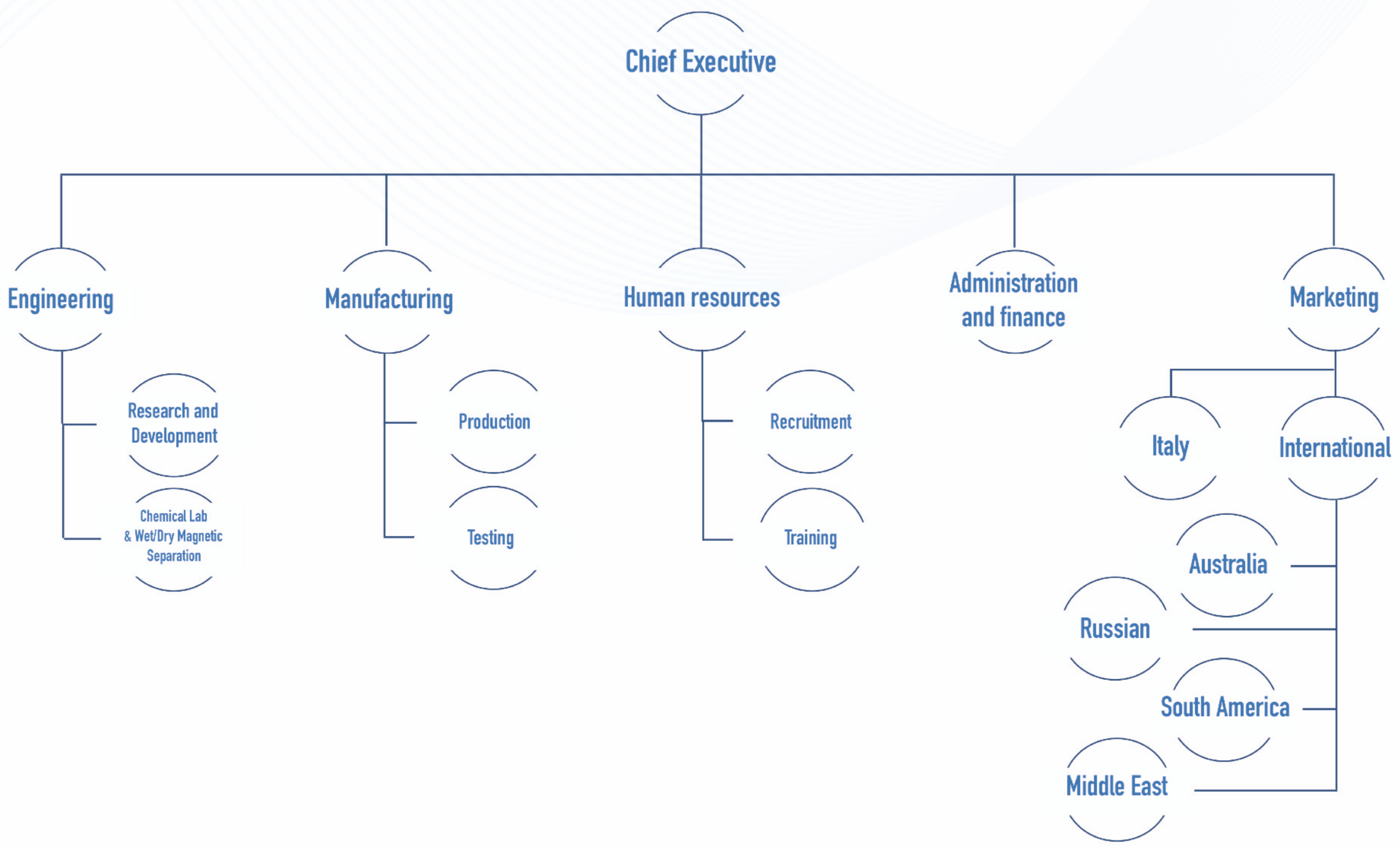

Our Company Structure

Departments

Technical Department

Operate since: 1979;

10 Employees: 2 engineers and 8 mechanical experts;

Office surface: 150 mq

Production unit & customer Service center

Operate since: 1979;

10 Employees

Plants surface: 6000 mq

Electrical Unit and automation

Founded in: 1964;

40 employees

Plants surface: 2700 mq

International production unit & customer service center

Operating: 1979;

25 employees

Plants surface: 12.000 sqm

Sales and administrative department

Operating: 1979;

5 employees: 2 commercial employees, 1 senior manager, 1 administrative manager, 1 foreign customers manager;

Plants surface: 110 sqm

Our magnets are among the most powerful available on the market and are manufatured to be installed in our magnetic systems

At Magnetense we have a different vision than our competitors. Our engineers and commercial staff:

– design and build powerful and efficient magnets;

– conduct ongoing research and implement the results in our magnetic systems;

– talk with clients before, during and after sale;

– provide industry-standard warranty on magnets;

– provide proactive support to our customers;

– design systems in compliance with global occupational health and safety standards

Our production process

In the magnetic separation industry there are only few companies owning the entire production process.

Only some can boast that they produce magnetic raw materials and manufacture magnetic systems and Magnetense is one of them.

Magetense manufactures the ferrite and neodymium magnets that are used in their magnetic separation systems.

Their engineering team conducts raw material research and then develops, produces, and tests high-efficiency magnetic systems.

Our staff also provide technical advice to companies who have bought standard magnetic systems from competitors and often find weak mechanical structures.

Standard products available on the market normally offer very low magnetic performances as. 9.000 Gauss where it is required an effective magnetic power of 12.000 or 13.000 Gauss and use materials unable to best exploit the effective magnetic flux.

Magnetense aims to provide the best magnetic performance for all customers.

Power and efficiency are achieved by their systems resulting in higher efficiency and increased power available to your processes.

To maintain their Magnetense promise Magnetense magnetic systems include:

1. Magnetic efficiency;

2. 3D design to account each efficiency reduction factor;

3. Taylor-made design on the base of your process needs.

OUR SERVICES

– Magnetic system performance assessments

– Plant design consultations and drawings

– Field surveys

– Application assistance

– Design of 3D magnetic systems and machines

Customer benefits include:

– Magnetic efficiency;

– New generation engineering: going beyond the limits of our older generation magnetic systems to increase your plant safety and secure continuous production;

– Thanks to stronger structures our systems feature optimal resistance with low structural weight;

– Our machines comply with areas 21 and 22 ATEX standards for in all applications where specific safety criteria are required.

This post is also available in: Italian